Due to extreme heat in the Middle East climbing up to 50°C in the height of summer, the necessity for reliable gas detection is critical. In this blog, we’re focusing on the requirement for detection of hydrogen sulphide (H2S)- a long running challenge for the Middle East’s gas detection industry.

By combining a new trick with old technology, we’ve got the answer to reliable gas detection for environments in the harsh Middle Eastern climate. Our new High Temperature (HT) H2S sensor for XgardIQ has been revisited and improved by our team of Crowcon experts by using a combination of two ingenious adaptations to its original design.

In traditional H2S sensors, detection is based on electrochemical technology, where electrodes are used to detect changes induced in an electrolyte by the presence of the target gas. However, high temperatures combined with low humidity causes the electrolyte to dry out, impairing sensor performance so that the sensor has to be replaced regularly; meaning high replacement costs, time and efforts.

In traditional H2S sensors, detection is based on electrochemical technology, where electrodes are used to detect changes induced in an electrolyte by the presence of the target gas. However, high temperatures combined with low humidity causes the electrolyte to dry out, impairing sensor performance so that the sensor has to be replaced regularly; meaning high replacement costs, time and efforts.

Making the new sensor so advanced from its predecessor is its ability to retain the moisture levels within the sensor, preventing evaporation even in high temperature climates. The updated sensor is based on electrolytic gel, adapted to make it more hygroscopic and avoiding dehydration for longer.

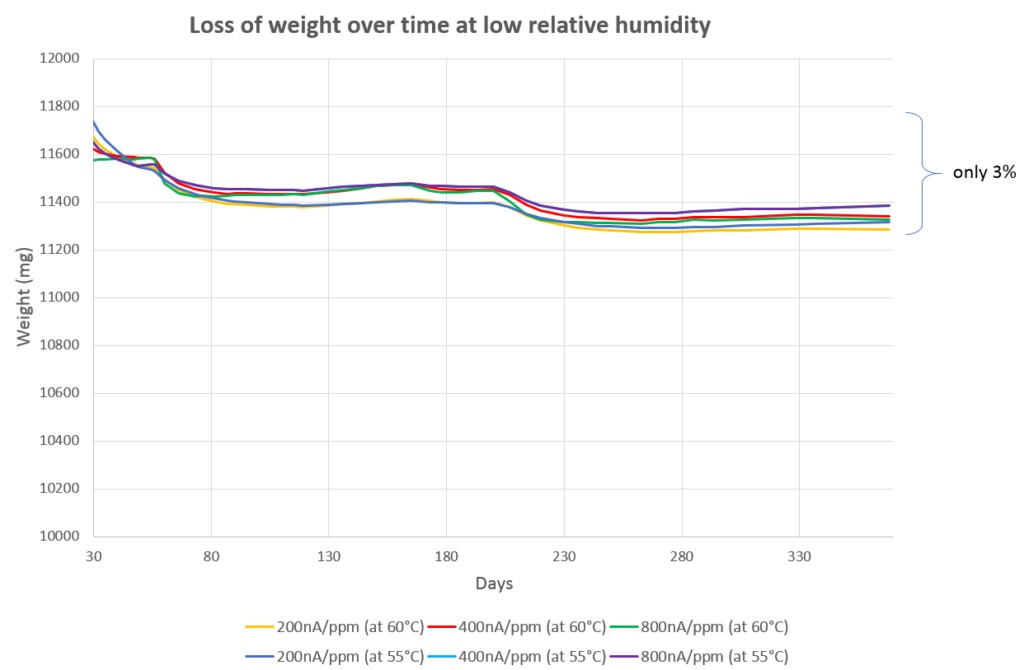

As well as this, the pore in the sensor housing has been reduced, limiting the moisture from escaping. This chart indicated weight loss which is indicative of moisture loss. When stored at 55°C or 65°C for a year just 3% of weight is lost. Another typical sensor would lose 50% of its weight in 100 days in the same conditions.

For optimal leak detection, our remarkable new sensor also features an optional remote sensor housing, while the transmitter’s displays screen and push-button controls are positioned for safe and easy access for operators up to 15metres away.

The results of our new HT H2S sensor for XgardIQ speak for themselves, with an operating environment of up to 70°C at 0-95%rh, as well featuring a 0-200ppm and T90 response time of less than 30 seconds. Unlike other sensors for detecting H2S, it offers a life expectancy of over 24 months, even in tough climates like the Middle East.

The answer to the Middle East’s gas detection challenges fall in the hands of our new sensor, providing its users with cost-effective and reliable performance.

Click here for more information about the Crowcon HT H2S sensor.

The series is based on true events from the 1986 nuclear disaster in the then USSR; the largest uncontrolled radioactive release into the environment ever recorded. The accident resulted in an untold number of fatalities, as well as serious social and economic disruption for large populations within the USSR and beyond.

The series is based on true events from the 1986 nuclear disaster in the then USSR; the largest uncontrolled radioactive release into the environment ever recorded. The accident resulted in an untold number of fatalities, as well as serious social and economic disruption for large populations within the USSR and beyond. Working in the office makes it easy to focus on the individual tasks and get detached from how our products are making a difference to people’s lives. One of our customers was kind enough to facilitate an onsite visit so that Andrea (our Halma Future Leader on a marketing placement) could see first-hand how our products are used and who the end users are. This meant a visit to an oil refinery to see where our Crowcon portable gas detectors are used.

Working in the office makes it easy to focus on the individual tasks and get detached from how our products are making a difference to people’s lives. One of our customers was kind enough to facilitate an onsite visit so that Andrea (our Halma Future Leader on a marketing placement) could see first-hand how our products are used and who the end users are. This meant a visit to an oil refinery to see where our Crowcon portable gas detectors are used.