In many situations, workers must perform pre-entry gas checks, to make sure that a confined space is safe before entering. This is often a requirement arising from risk assessment or to allow the issuing of permits to work, or is simply needed because the area is inherently risky. Whatever the reason, using a pumped device in conjunction with a sampling tube is a great way to perform pre-entry checks to check that a confined space is safe before entry.

However, taking measurements in this way brings its own set of challenges and dangers, and when using Crowcon products in pumped or manual sampling modes, all operators should take care to follow these instructions:

• It is strongly recommended that, before proceeding, a function check is performed using the pump and sample tube with the gas/vapour to be detected.

• To reduce the risk of absorption of the gas/vapour in the sample tube, ensure the temperature of the sampling tube is above the flashpoint temperature of the target vapour.

• Ensure the monitor is correctly calibrated for the target gas/vapour.

• Only use the sample tube supplied by Crowcon. It is strongly recommended that ‘reactive gas tubing’ (part no. AC0301) is used for sampling gases/vapours that are likely to be adsorbed (for example, toluene, chlorine, ammonia, hydrogen sulphide, ozone, hydrogen chloride, NOx, etc).

• Keep the sample tube length as short as possible.

• Please allow sufficient time for the gas/vapour to reach the sensor; allow at least 3 seconds per metre plus the normal T90 response time of the sensor (typically 30–40 seconds).

In addition, please note that some of the gases that can be measured by our gas detection products are classified as ‘reactive’ gases.

A reactive gas will react with, or be absorbed by, the material(s) with which it comes into contact. As a result, the gas concentration reaching the sensor can be reduced, leading to an incorrect reading.

The following list includes some (but not all) reactive gases, which are listed with the appropriate calibration gas. Please contact Crowcon for specific gas concentration information and cross-calibration values).

Target Gas Calibration Gas

Ozone (O3) Ozone (via O3 generator)

Hydrogen Chloride (HCL) Hydrogen Chloride

Hydrogen Fluoride (HF) Hydrogen Chloride or Sulphur Dioxide

Chlorine (Cl2) Chlorine (via Cl2 generator)

Fluorine (F2) Chlorine (via Cl2 generator)

Chlorine Dioxide (ClO2) Chlorine (via Cl2 generator

Phosgene (COCl2) Chlorine (via Cl2 generator)

Sulphur Dioxide (SO2) Sulphur Dioxide

Nitrogen Dioxide (NO2) Nitrogen Dioxide

Nitrogen Monoxide (NO) Nitrogen Monoxide

Ammonia (NH3) Ammonia

• It is very important that the appropriate accessories and precautions are applied when measuring, calibrating or bump testing sensors that are targeting reactive gasses

When taking sample measurements:

• Use Teflon, FEP or PTFE tubing; the tube length must be kept as short as possible (<50 cm). Avoid connectors and unions.

• Allow the sample to flow through the regulator/pipe for at least 3 minutes, for initial absorption to occur, before attempting to get a reading.

When calibrating the above points apply in addition to the following:

• The recommended gas flow-rate is 0.5 litres per minute.

• Gas generators are recommended, instead of gas cylinders, for some very unstable gases, especially where very low ppm concentrations are required.

• Use only stainless steel regulators for cylinder gas.

• Ensure the correct calibration adaptor is used, appropriate to the specific product.

Following the above guidance will allow your pumped devices pre-entry checks to deliver accurate measurements – even with reactive gasses – and will keep staff safe and well.

Striking a Balance

Striking a Balance

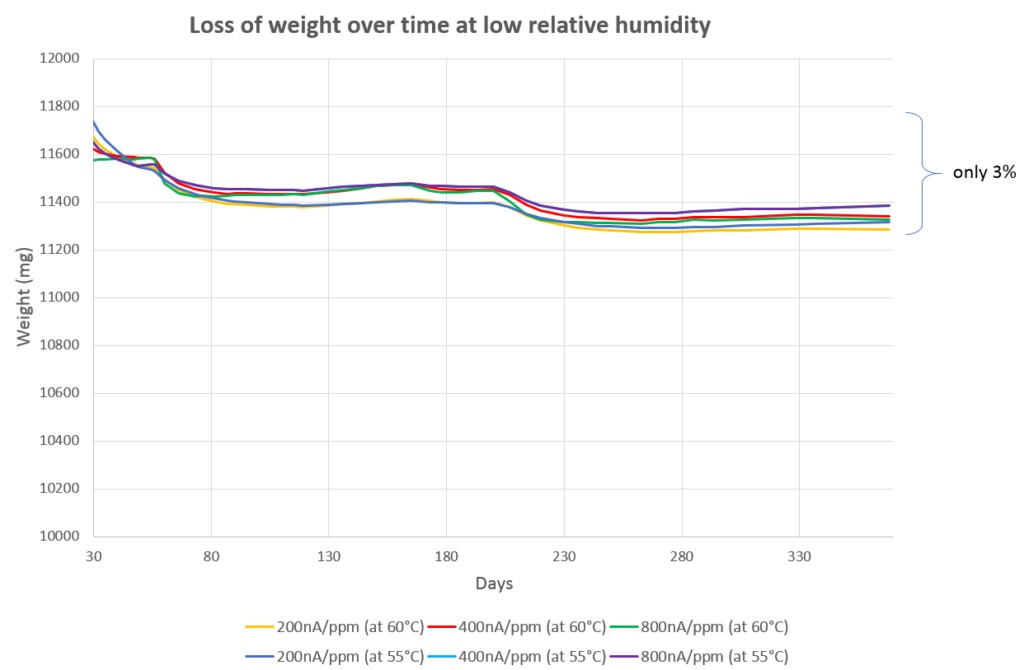

In traditional H2S sensors, detection is based on electrochemical technology, where electrodes are used to detect changes induced in an electrolyte by the presence of the target gas. However, high temperatures combined with low humidity causes the electrolyte to dry out, impairing sensor performance so that the sensor has to be replaced regularly; meaning high replacement costs, time and efforts.

In traditional H2S sensors, detection is based on electrochemical technology, where electrodes are used to detect changes induced in an electrolyte by the presence of the target gas. However, high temperatures combined with low humidity causes the electrolyte to dry out, impairing sensor performance so that the sensor has to be replaced regularly; meaning high replacement costs, time and efforts.

Who doesn’t love a summer BBQ? Come rain or shine we light up our BBQs with usually the only worries being whether it will rain, or the sausages are fully cooked through.

Who doesn’t love a summer BBQ? Come rain or shine we light up our BBQs with usually the only worries being whether it will rain, or the sausages are fully cooked through. The series is based on true events from the 1986 nuclear disaster in the then USSR; the largest uncontrolled radioactive release into the environment ever recorded. The accident resulted in an untold number of fatalities, as well as serious social and economic disruption for large populations within the USSR and beyond.

The series is based on true events from the 1986 nuclear disaster in the then USSR; the largest uncontrolled radioactive release into the environment ever recorded. The accident resulted in an untold number of fatalities, as well as serious social and economic disruption for large populations within the USSR and beyond.